About Sinotech

Sinotech provides a flexible solution for vessel operators with its CCS modular design. Suitable for both existing and newbuild vessels, the Sinotech units can be installed in combination with an existing exhaust gas cleaning system or scrubber. Additionally, if your vessel runs on low sulfur fuel oil, it can operate as a stand-alone CCS system. The Sinotech scrubber is available in both open-loop and hybrid versions to suit your operational needs.

How Sinotech can help you?

Patented Amine solution can be stripped of the absorbed CO2 at 90°C, 25% below the industry standard. Along with the efficient heat recovery design, it results in a very low energy demand per ton of captured CO2. The Sinotech liquefaction process is the most efficient way to store CO2 simplifying onshore disposal logistics.

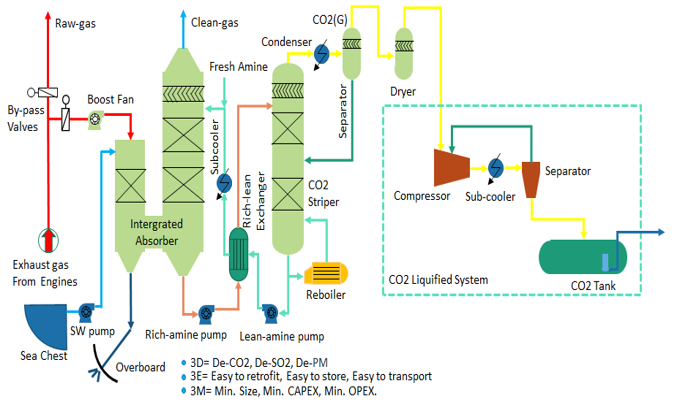

Sinotech CCS process consists of four stages: Scrubbing Absorption, De-sorption and Storage

The hot exhaust gas from main and aux engines as well as boiler is cooled down from a capacity 300°C to 30°C and sulphur dioxide is removed, in line with IMO 2020 sulfur discharge limits. In case of a stand-alone CCS, this would be simple quenching stage to cool down the exhaust gas with sea water.

The cool exhaust is moving upwards while amine solution droplets rain down. During this interaction between gas and liquid, the amine solution absorbs CO2. The clean exhaust is discharged into the atmosphere while the rich amine solution is collected at the bottom of the tower. A droplet separator at the top of the tower makes sure that amine droplets are kept in the process.

The rich amine solution heated up by means of a heat exchanger and a reboiler. The high temperature releases the CO2 so that the lean amine solution can be collected at the bottom of the desorption tower. Its residual thermal energy is recovered in the heat exchanger before the amine solution is recirculated into the second stage. The CO2 is collected at the top of the de-sorption tower and any evaporated amine solution is recovered in the condenser.

The CO2 is compressed and cooled down to 2.4 MPa and -20°C respectively which reduces its volume by 99.9% before it is stored in cryogenic tanks.

Plug and Play CO2 Removal

The liquified carbon dioxide can be stored in IMO Type C tanks as well as 20’ or 40’ tank containers. Due to Sinotech’s simple CO2 off-loading, the second option is especially suitable for CCS installations on container vessels.

The liquid CO2 can be offloaded in port to quayside tank trucks, CO2 tank barges or a permanent onshore CO2 reception facility. The optimum system setup and CO2 recovery rate is selected based upon several factors including the vessels trade route, onboard storage capacity and preferred discharge locations.

How Scanvi-Interyards work with Sinotech

Scanvi-Interyards represents Sinotech in the Norwegian market since 2023. Together with the experts at Sinotech we offer technical and commercial support to Norwegian ship owners and shipyards.

Latest from Sinotech

Armada Technologies Announces Contract with CoolCo for Air Lubrication Installation

Oslo, Norway [20 February 2024] We are pleased to announce Armada Technologies’ collaboration with Cool Company Ltd (CoolCo), a leading LNG carrier company. Under this partnership, Armada will design, engineer,…

Scanvi-Interyards Partners with CLIIN Robotics

We’re excited to share our new partnership with CLIIN Robotics. This partnership fortifies our commitment to efficiency, sustainability, and cutting-edge solutions in ship maintenance. CLIIN Robotics introduces a revolutionary solution…