Yokogawa ROTAMASS-series Coriolis Mass Flow Meters

The box-in-box designed highly accurate and reliable ROTAMASS-series Coriolis mass flow meter from Yokogawa is the main component.

The flow meter has proven itself in use for many years, and by choosing this instrument you are sure to have one of the best possible setups when it comes to measuring flow on board your vessel.

Naturally the flow meter is DNV-GL approvad and has proven it self by 1000’s of field and vessel engine room installations.

Contact us for more information about utilization, implementation and price.

Accurate and reliable fuel flow measurement

With flow measurement based on the Coriolis principle, you will get direct measurement of density and the actual mass flow in your pipes. By eliminating the need for various conversions, such as temperature and density factors, sources for wrongful calculations and offsets are effectively eliminated.

As the Coriolis principle will have an effect on the measuring tubes of the flow meter from very low flow rates, the measuring span of the Coriolis mass flow meter is often of greater than that of many other measuring principles, while simultaneously maintaining a higher accuracy across the entire range.

Main advantages and benefits:

- Direct mass, density and temperature measurement

- Vibration-resistant due to the box- in box system

- No straight piperun required

- Fast and uncomplicated commissioning

- Maintenance-free operation

- Selfmonitoring of the entire flow meter

No compensations equal fewer sources for miscalculations

The fact that the Yokogawa ROTAMASS Mass Flow Meter, in addition to the directly measured mass flow, can provide directly measured density and calculated volumetric flow, means that all measurement translates to a signal without the need of a flow computer or another source for compensation or conversion. This provides a setup with fewer sources for error and mistakes, and by adding signals for sensor errors and self-diagnostics as well, it ensures that the signals you get are less likely to get tampered with and are ready more or less as they are for further use in other systems.

Well-suited for demanding environments

In general terms, Coriolis Mass Flow Meters are relatively sensitive instruments. They need to be installed in well-aligned piping, so they are not affected by stress, minor movements and vibration in the system. The Yokogawa ROTAMASS-series is designed with a unique and patented ‘box-in-box’ feature, that makes it far less sensitive to stress, movement and vibrations. For installations in demanding and harsh conditions like on a ship, the ROTAMASS-series proves itself ideal with its more robust layout.

Minimize maintenance on board

The Coriolis Mass Flow Meter is in general an instrument that requires very little attention once it is installed correctly. As it has no moving parts and no sub-millimeter tolerances, the risk of breakdown or clogging is minimal. Within the flow meter itself, there is literally no parts that needs replacement over the lifetime of the instrument. And since the sensor is insensitive to particles and debris in the stream going through it, there is no requirement towards filtering the fuel before the flow is measured.

Cost effective setup

Eliminating the need for regular maintenance of the flow meter reduces the attention required in itself. But when you avoid installing a filter before the instrument, it further adds to the time saved as monitoring of the pressure drop over the filter and the periodical filter cartridge changes are also obsoleted. All the time and required attention that a typical volumetric flow meter with a pre-filter installation requires, can be spend on more productive and performance enhancing initiatives, thereby allowing the crew to make the vessel more cost efficient.

The cost of saving money on instruments

In general terms, you most often get what you pay for when it comes to instrumentation. But there is also the factor of sourcing the correct instrument with a suitable setup. So, the total cost of an instrument can be divided into two categories; the actual cost of the instrument in monetary terms, and the cost of time spend on making sure the suitable instrument is selected and installed correctly. And cutting cost too much on either of the two categories can result in an excessively high final cost.

Select the correct instrument – for now and the future

Taking your time to select the correct flow meter providing the functionality required, not only now but also for any future use, is always a financially sound investment. In some cases, the needs and requirements call for a simple and low-cost instrument providing flow rate indications, and in these cases, you should not have more than that. But for most applications, a future-proven and reliable flow meter is of much greater value to both operator and owner. Getting the right flow meter for the intended use and application with the right features and possibilities, can not only ensure that the implementation is executed with a minimum of effort, but also prevent the need of an upgrade to a more suitable instrument at an early stage of the instruments expected lifespan.

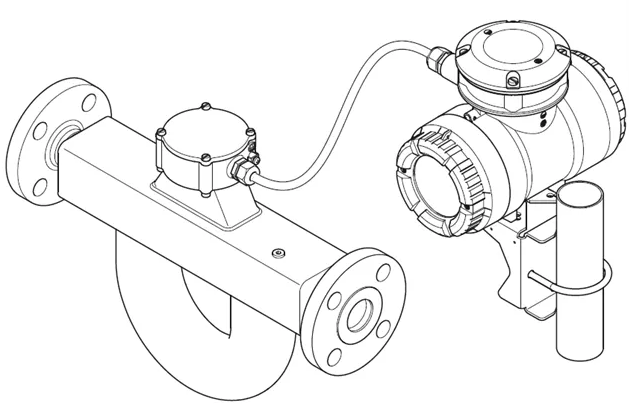

The flow meter setup we use onboard vessels we choose the flow meter tube with an seperate converter, this makes the flow meter much more resistant to vibrations in the fuel line, see the picture below.

How a Coriolis Mass Flow Meter works

The Coriolis effect is a universal physical phenomenon found in masses moving within a spinning or moving frame. In this case, the Coriolis effect is present as we have fuel flowing through a pipe – but it is only present because the sensor pipe is oscillating. The oscillation is key to obtaining the Coriolis effect, and since the Coriolis effect is a well-understood phenomenon, it can be used to accurately determine the mass flow in the sensor pipes.

The sensor pipes of a Coriolis mass flow meter are typically a set of paired and U-shaped pipes, but many shapes of sensor pipes are used by different makers in a wide variety of Coriolis mass flow meter models. At the bottom of the ‘U’ an electromagnetic vibration generator oscillates the sensor pipes, and on each of the ‘legs’ of the U-shaped pipe a sensor detects the frequency of the oscillation.

At zero flow, the oscillation of the ‘legs’ will be synchronized with both sensors registering the same pulse frequencies at the same time. When a flow is introduced through the sensor piping, the U-shaped sensor pipe will start to ‘wiggle’ due to the Coriolis effect, as the moving mass will ‘delay’ the upstream pulse. The two sensors will now experience an offset in the pulses, and the larger the offset the larger the flow is.

Depending on the density of the media in the pipe, the electromagnetic vibration generator will have to adjust the power (current) applied to get the oscillation characteristics needed. The current applied to the electromagnetic vibration generator is directly correlated with the density of the media and can therefore be directly translated into a density measurement – and this applies regardless of flow.

Combining these two factors provides the Coriolis mass flow meter the ability to measure mass flow directly.

Applications

In general, a Coriolis-principle based mass flow meter can be utilized to measure flow in most cases. Whether the flow is constituted by fluid or gas, a Coriolis mass flow meter can do the job. The Yokogawa ROTAMASS can be used for all types of fuel available for ships, whether it is heated oils or very cold liquid natural gas or anything in between.

The ROTAMASS Coriolis Mass Flow Meter is used for fuel consumption measurement on all fuel types, fuel transfer measurements on all fuel types, bunker operations on all fuel types and for some lube oil applications.

The ROTAMASS is available for use in safe as well as for hazardous areas, and as there are no requirements in regard to straight piping before or after the Coriolis Mass Flow Meter it can be retrofitted into almost any pipeline. The only requirements that are present for the Coriolis Mass Flow Meter, regardless of maker, is that the flow must either be horizontal or upwards vertical, and the media flow shall be air free.

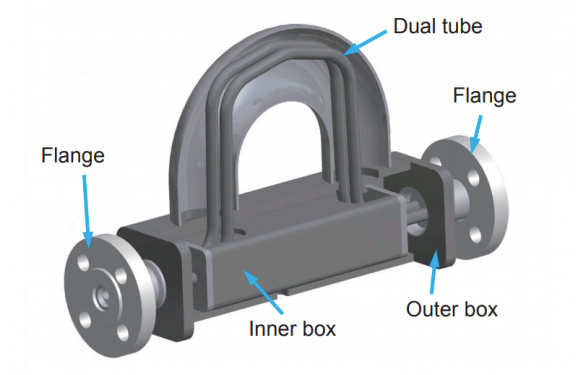

The ROTAMASS box-in-box Mass Flow Meter construction

The unique and patented box-in-box design of the ROTAMASS Mass Flow Meter provides numerous advantages. The principle of the design is quite simple. An outer box has the inlet and outlet connections attached to it. The inner box has the sensor pipes connected to it. This way, the outer box becomes the part that ensures the position and fixation of the instrument, while the inner box secures the sensor pipes in a fixed position, isolating them from any stress in the piping system.

Installations are simplified as the instrument is less sensitive to stress caused by misalignment in the pipeline. Furthermore, any minor motion and movement in the pipeline will have significantly less influence on the flow meter, as the stress caused by these factors, are absorbed by the outer box and deflected from the inner box. As most of the stress from the surrounding piping system is diverted around the sensor piping, the result is a more accurate measurement and less frequent need for zero-point adjustments.

Installation and afterwards

The ROTAMASS Coriolis Mass Flow Meter is easy to install. As with most instruments, it does require that the piping in which is has to be installed, is somewhat aligned, but compared to other similar instruments, the box-in-box design does expand the tolerances to a great extent.

Once the installation and commissioning are over, and the Flow Meter has been put into use, we are always ready to assist with any troubleshooting, faultfinding and service that might arise a need for. Our delivery does not stop with the Flow Meter – we want you to benefit from your Coriolis Mass Flow Meters for many years. And we are sure that you will.